Top Titanium Knee Replacement Manufacturers

As the demand for joint replacement surgery continues to rise worldwide, titanium knee replacement manufacturers play an increasingly crucial role in delivering advanced, durable, and patient-friendly implants. These manufacturers aren't simply producing parts—they're redefining the standards for surgical performance, patient recovery, and long-term comfort.

The best titanium knee replacement manufacturers combine engineering excellence with medical insight, creating implants that mimic natural movement, reduce recovery times, and minimize the risk of allergic reactions or mechanical failure. The choice of manufacturer can directly influence a patient’s quality of life, making it essential for hospitals, clinics, and orthopedic surgeons to partner with brands that prioritize research, innovation, and clinical outcomes.

Today’s leading producers operate with global certifications, ISO-compliant systems, and a strong commitment to continuous improvement. They don’t just build implants—they engineer trust, longevity, and confidence for surgeons and patients alike.

What Sets High-End Titanium Knee Replacement Manufacturers Apart

Not all manufacturers are created equal. What truly distinguishes premium titanium knee replacement manufacturers from the rest is their ability to integrate every stage of the production process into a controlled, quality-driven ecosystem.

Our facility, for example, is equipped with cutting-edge production technology and advanced equipment, supported by stringent quality management systems and experienced technical teams. From CNC machining centers to precision surface treatment, each step is engineered for perfection. We use only premium-grade titanium alloy materials known for their biocompatibility, fatigue strength, and corrosion resistance.

Moreover, expert technical support and collaborative R&D efforts allow us to customize implants based on patient morphology, surgeon preferences, and regional anatomical variations. This flexibility helps medical professionals achieve superior surgical outcomes, which in turn enhances our reputation as one of the most dependable titanium knee replacement manufacturers globally.

With continuous investments in material science, biomechanics, and digital design, top-tier manufacturers are not only meeting today’s demands but also driving tomorrow’s orthopedic breakthroughs.

Titanium Knee Replacement Manufacturers and Material Excellence

The success of a knee implant relies heavily on the material used. That’s why leading titanium knee replacement manufacturers place a strong emphasis on sourcing and processing the finest titanium alloys. The specific choice of alloy—often Grade 5 titanium (Ti-6Al-4V)—offers a combination of strength, lightness, and exceptional corrosion resistance, ideal for long-term implantation in the human body.

Titanium also has a modulus of elasticity closer to natural bone than other metals, helping prevent stress shielding and promoting healthy bone in-growth. Manufacturers who understand this subtle biomechanical interplay produce implants that perform more naturally and last longer.

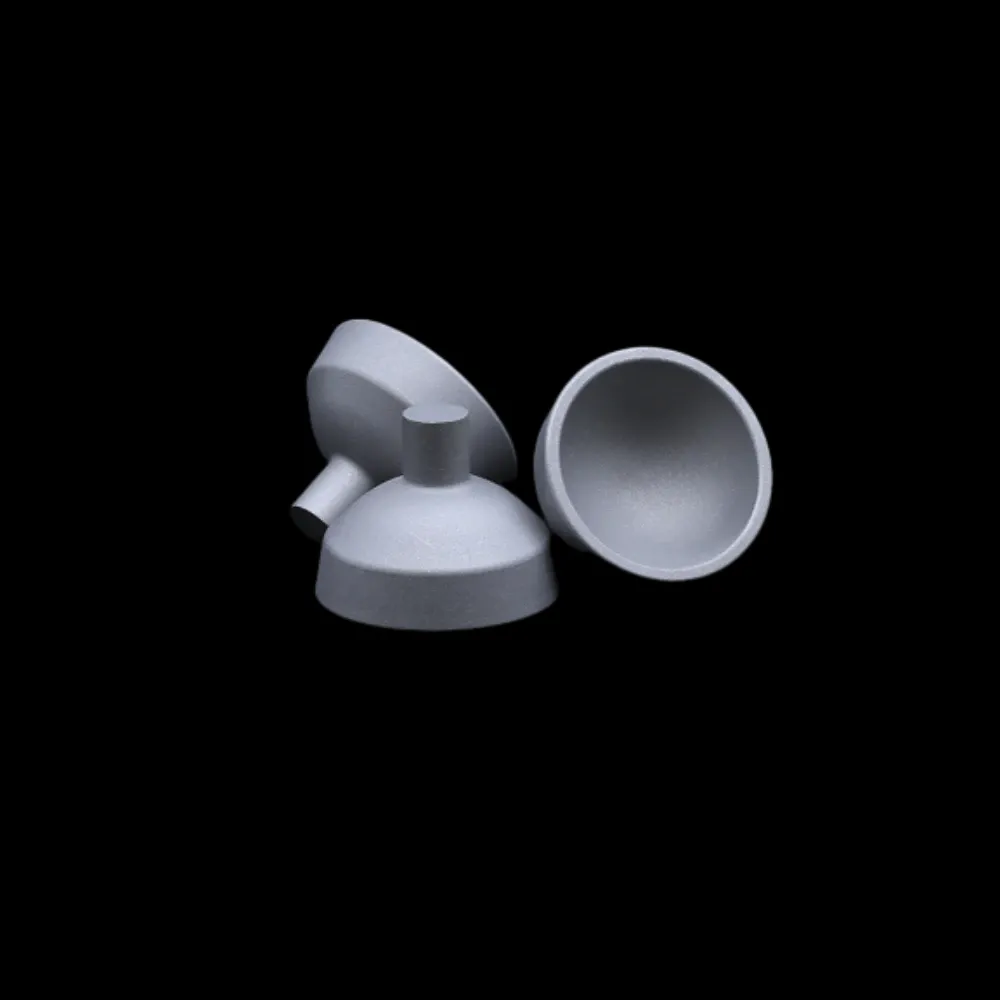

Beyond raw material, surface modification techniques such as plasma spraying, HA coating, or 3D-printed porous structures further enhance bone integration and implant stability. When manufacturers control the entire process—from raw titanium powder to final sterilized packaging—the result is a high-performance product that delivers reliability in every surgery.

That’s why when you select implants from trusted titanium knee replacement manufacturers, you’re not just buying a product—you’re buying decades of scientific refinement.

Global Reach and Custom Solutions by Titanium Knee Replacement Manufacturers

The best titanium knee replacement manufacturers aren’t confined by borders. With global logistics capabilities, regulatory certifications, and multilingual support teams, these manufacturers serve hospitals and healthcare systems across North America, Europe, Asia, and the Middle East.

In international markets, success depends on customization and responsiveness. Our R&D teams work closely with local surgeons to tailor implant geometries that match population-specific anatomical characteristics. Whether it’s a high-flexion design for Asian markets or robust primary components for Western demographics, adaptability is key.

Additionally, our advanced digital modeling and prototyping services allow surgeons to preview and simulate the implant fit before surgery—greatly reducing intraoperative guesswork. OEM/ODM partnerships are also welcome, giving distributors and brands the opportunity to bring private-labeled, high-quality titanium implants to market quickly.

Through this hybrid of global scale and local responsiveness, titanium knee replacement manufacturers are expanding access to world-class orthopedic care in both developed and emerging healthcare systems.

Choosing the Right Titanium Knee Replacement Manufacturers for Your Practice

For surgeons, hospitals, and medical distributors, selecting the right titanium knee replacement manufacturers is more than a procurement decision—it’s a clinical and reputational one. The manufacturer you align with impacts patient recovery, revision rates, and your own credibility as a care provider.

Look for a partner that offers transparent documentation, full traceability, and CE/FDA/ISO certifications. In addition, assess their capacity for after-sales service, product availability, and ongoing training programs. A truly reliable manufacturer provides more than implants—they deliver peace of mind.

Our manufacturing ethos is built on long-term relationships. We provide clinical data, surgeon support kits, trial instruments, and training courses to ensure every surgical team is fully confident and equipped. Through innovation, collaboration, and precision, we continue to serve as a trusted global supplier for orthopedic excellence.

Titanium knee replacement manufacturers FAQs

What qualifications should I look for in titanium knee replacement manufacturers?

Look for manufacturers with ISO 13485 certification, CE Marking, FDA approval, and a documented quality control process. These certifications ensure that the titanium knee replacement manufacturers meet rigorous standards for medical device safety, production consistency, and biocompatibility. It's also important to verify if they conduct clinical trials or offer published data on implant performance.

How do manufacturers ensure the quality of titanium knee replacement implants?

Top titanium knee replacement manufacturers use advanced inspection systems, such as 3D scanners, coordinate measuring machines (CMMs), and fatigue testing rigs to verify structural integrity. In addition, each implant typically goes through multiple stages of cleaning, sterilization, and packaging within controlled environments. Many also apply traceability markings for post-market surveillance and batch recall if necessary.

Why is titanium preferred over other metals in knee replacements?

Titanium is lightweight, corrosion-resistant, and has excellent biocompatibility. Its elastic modulus is closer to that of human bone, reducing stress shielding and encouraging bone integration. Unlike cobalt-chromium alloys, titanium also has a very low allergy risk. This makes it an ideal material for implants that must last decades inside the human body.

Do titanium knee replacement manufacturers offer customized solutions for different markets?

Yes, most leading titanium knee replacement manufacturers offer design variations based on geographic and demographic needs. Implants may differ in sizing, curvature, or flexibility depending on the target population. Some manufacturers also collaborate directly with surgeons to develop patient-specific implants or high-flexion models suited to local cultural habits and mobility demands.

Can hospitals order OEM or private-labeled implants from titanium knee replacement manufacturers?

Absolutely. Many manufacturers provide OEM (Original Equipment Manufacturer) or private-label services. This allows hospitals, distributors, or healthcare brands to offer titanium implants under their own label while leveraging the manufacturer’s production capacity, certifications, and quality standards. It’s an effective way to enter new markets or expand your brand presence without compromising on product excellence.

Get a Custom Solution!

Contact Us To Provide You With More Professional Services