Exploring the Benefits and Titanium Knee Replacement Cost

In recent years, titanium knee replacement has become a leading choice in orthopedic surgery due to its exceptional strength, biocompatibility, and longevity. Patients and surgeons alike are increasingly turning to titanium-based implants as they offer superior durability and performance compared to traditional materials.

Understanding the titanium knee replacement cost is crucial for anyone considering this life-changing procedure. Although titanium implants tend to be more expensive upfront than other materials, their benefits—such as corrosion resistance, lightweight nature, and reduced allergic reaction risks—make them a valuable investment in long-term joint health.

The titanium knee replacement cost varies depending on factors like the implant design, surgical facility, geographic location, and insurance coverage. While the initial cost may seem higher, many patients find that the improved durability and faster recovery reduce overall medical expenses over time.

With continuous innovation, titanium knee replacement technology evolves, promising even better outcomes. This progress attracts a growing number of patients seeking to regain mobility and live an active life with confidence.

Why Titanium Alloy Knee Replacement Is Revolutionizing Joint Surgery

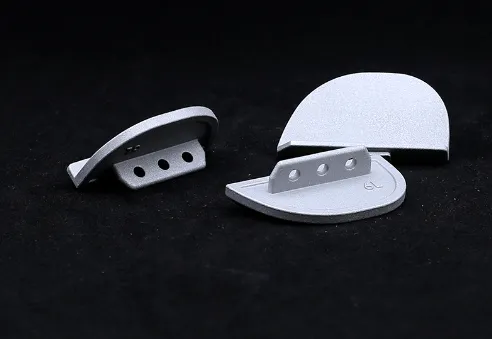

The emergence of titanium alloy knee replacement has revolutionized the way orthopedic implants are designed and manufactured. Unlike pure titanium, titanium alloys combine the metal with other elements such as aluminum and vanadium to enhance mechanical properties without compromising biocompatibility.

Titanium alloy knee replacement components are known for their high strength-to-weight ratio, excellent fatigue resistance, and superior corrosion resistance. These qualities make the alloy an ideal material to withstand the mechanical stresses of daily activities while minimizing wear on the implant surface.

Moreover, the porous surface design commonly used in titanium alloy knee replacement promotes bone in-growth, ensuring stable fixation and reducing the risk of implant loosening. This innovative approach helps improve the longevity of the prosthesis and patient satisfaction.

Manufacturers continually invest in research and development to improve titanium alloy knee replacement products, focusing on enhancing implant geometry, surface coatings, and compatibility with minimally invasive surgical techniques. This dynamic evolution ensures that patients receive state-of-the-art care tailored to their specific needs.

Choosing Reliable Titanium Knee Replacement Manufacturers: What You Need to Know

Selecting trusted titanium knee replacement manufacturers is paramount to ensure implant quality, safety, and regulatory compliance. The orthopedic implant market features a wide array of suppliers, but not all meet the rigorous standards required for medical devices.

Reputable titanium knee replacement manufacturers employ cutting-edge production technology, advanced materials testing, and stringent quality management systems. They adhere to international certifications such as ISO 13485 and FDA approval processes, guaranteeing the reliability and safety of their products.

Furthermore, these manufacturers offer comprehensive technical support, customized design services, and collaborations with surgeons to develop implants that match patient anatomy and surgical preferences. This close partnership enhances surgical outcomes and fosters continuous innovation.

When researching titanium knee replacement manufacturers, healthcare providers and patients should prioritize companies with proven clinical success, transparent supply chains, and commitment to sustainable manufacturing practices. This diligence helps minimize risks and ensures access to the best possible implants.

Titanium Knee Replacement: Combining Innovation, Durability, and Patient-Centered Care

The ultimate goal of any titanium knee replacement is to restore mobility, alleviate pain, and improve life quality. Modern titanium implants leverage advanced metallurgy and design to deliver these benefits with unmatched reliability.

The lightweight nature of titanium reduces implant mass without sacrificing strength, making it easier for patients to adapt and regain natural movement. Additionally, the metal’s biocompatibility decreases inflammation and the risk of allergic reactions, promoting faster healing and fewer complications.

From patient-specific implant modeling to robotic-assisted surgery, the integration of technology with titanium knee replacement further enhances surgical precision and implant fit. This synergy optimizes implant longevity and functional outcomes.

Overall, investing in a high-quality titanium knee replacement supported by skilled surgeons and trusted manufacturers represents a significant step towards a more active, pain-free lifestyle for patients worldwide.

titanium knee replacement FAQs

What factors influence the titanium knee replacement cost?

The titanium knee replacement cost is influenced by the implant’s design complexity, material purity, manufacturing processes, surgical facility fees, surgeon expertise, and geographic location. Insurance coverage and healthcare plans also significantly impact the patient’s out-of-pocket expense.

How does titanium alloy knee replacement differ from other materials?

Titanium alloy knee replacement uses a blend of titanium with metals like aluminum and vanadium to enhance strength and durability. Compared to cobalt-chromium or stainless steel, titanium alloys offer better corrosion resistance, lighter weight, and improved biocompatibility, reducing long-term complications.

What should I look for when choosing titanium knee replacement manufacturers?

Choose titanium knee replacement manufacturers with robust quality control, internationally recognized certifications (like ISO 13485), positive clinical outcomes, and strong customer support. Collaboration with healthcare professionals and a commitment to innovation are also key indicators of a reliable manufacturer.

Is titanium knee replacement suitable for all patients?

While titanium knee replacement is suitable for many patients, factors such as age, bone quality, allergy history, and activity level must be considered. A thorough consultation with an orthopedic surgeon will help determine if titanium implants are the best option.

How long does a titanium knee replacement last?

With proper care and lifestyle management, a titanium knee replacement can last 15 to 25 years or more. Advances in implant design and materials continue to improve longevity, reducing the likelihood of revision surgery.

Get a Custom Solution!

Contact Us To Provide You With More Professional Services